Step 1 - Check

Place all the parts provided on a clean and smooth surface, always away from soil/water.

Make sure you have all the hardware required for each bracket.

For other installation tips and instructions follow the manual that came with your set or download it below. It's especially important to refer to your vehicule manual in order to know the loading rate of your vehicule roof. Remember that the condition of your gutter and the weight of your rack/platform also may affect.

Place all the parts provided on a clean and smooth surface, always away from soil/water.

Make sure you have all the hardware required for each bracket.

We encourage installers to use a good silicone self-fusing tape, liquid sealant, high density thread seal tape or anaerobic sealant if you're planning a low-maintenance and long-lasting installation.

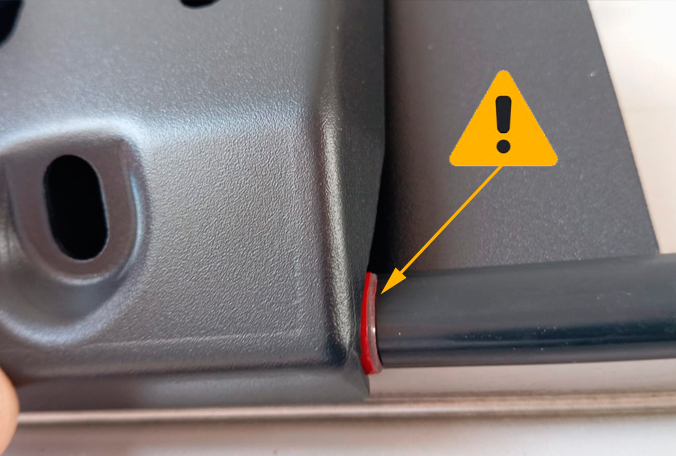

Clean the gutter and make sure there is nothing where you'll place the bracket.

If your gutters are not protected, use an acrylic tape or self adhesive and water resistant 15mm seal trims or mounting tape. Even butyl rubber or latex from a bike tube will do the job to isolate the bracket from the vehicle gutter.

Place the Weather Strip U Channel (rubber liner ) provided at the bottom of the bracket.

With help of a clean cloth, lay the bracket gently on your required location.

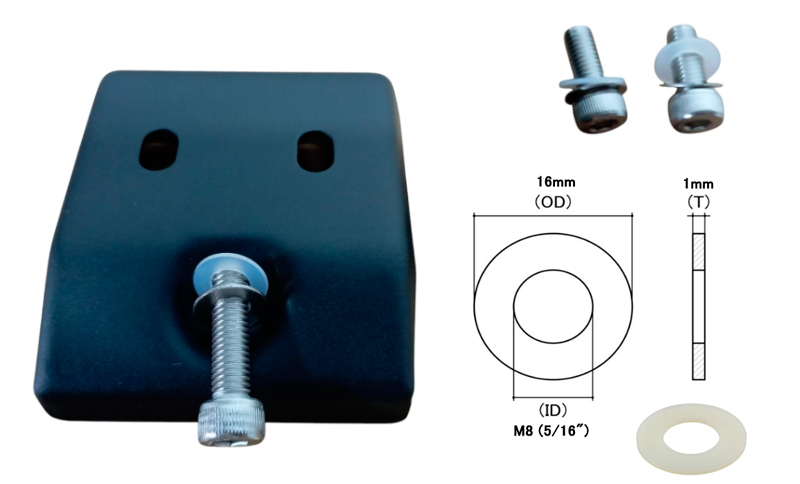

It's higly recommended to place nylon washers between the attachment substrate (bracket) and the stainless steel washer to avoid damaging the coating when installing.

For your comfort on the next step, place the long "Lock Bolt" on the bottom hole of the lock cap. If you're installing our OZ41 bracket place these 2 bolts evenly.

Gently position the lock cap over the bracket foot.

Screw the lock bolt to strongly secure the bracket to the definitive position. This bolt provide stability.

Screw the two safety bolts to make it extra safe and lock it permanently. These are specially helpful on rough roads.

Set another bracket on the opposite side of the roof.

Using a flat slat measure the distance side-to-side.

Remember that length of crossbar/rack affect aesthetics but there are also laws establishing specific limits.

Always protect your vehicle roof before proceed to fit your roof rack system.

We encourage installator/s to use an extendable crane or a mobile gantry crane to lift rack/platform/cage.

Everything should be ready by now to fit accesories and re-check the installation.

Metals rusts in soil or sand because it comes into contact with moisture and oxygen, a process accelerated by soil characteristics like salt content, pH, and microbial activity. Water acts as an electrolyte, and the soil provides moisture and oxygen for the reaction to occur, which forms iron oxide (rust).

Please avoid contact of the products with oil/sand/water!

Recommended maximum tightening Torque for our hardware M8 is 25Nm (handtight).

Power tools are NOT REQUIRED to install our product/s.

By using power tools you will damage the thread and coating of our products and eventually your vehicle gutter.

If your gutters are not protected, use an acrylic tape or self adhesive and water resistant 15mm seal trims or mounting tape. Even butyl rubber or latex from a bike tube will do the job to isolate the bracket from the vehicle gutter.

We encourage installers to use a good silicone self-fusing tape, liquid sealant, silicone or lanolin spray, high density thread seal tape or anaerobic sealant if you're planning a low-maintenance and long-lasting installation.

Bunnings sells BOSTON 50g Liquid Sealant .

It's higly recommended to put nylon washers between the attachment substrate (bracket) and the stainless steel washer to avoid galvanic corrosion .

As a reference, check metals used on your setup against this useful galvanic reaction chart for dissimilar metals .

If your vehicle is constantly expose to weather or you live in a environment with high salinity, use a rust preventer to protect your set-up creating a protective barrier against moisture, rust, soil and corrosion.

Rust is a slow process.

Just by looking after your product and checking its condition every 2-3 months you can extend its lifespan.

If touch up needed, we recommend Dulux Metalshield® Epoxy Enamel spray paint (note that colours may vary).

Main reason to avoid power tools when installing our product/s.

If one of the threads on the bracket was damaged, you can use a tap & die set to repair it or just place a thin lock nut behind.

This last method has been tested & proof to improve the resistance to stress up to +4 times in some of our models.

Your product colour will fade along the time. You can opt to restore the colour by spraying with clear coat, epoxy enamel or specific metal paint.

Dullux Australia Metalshield® Epoxy Enamel will add a long term protective layer already tested with amazing results on our carbon steel brackets.